AutoGrid® in-process

Determination of formability characteristics

AutoGrid® in-process

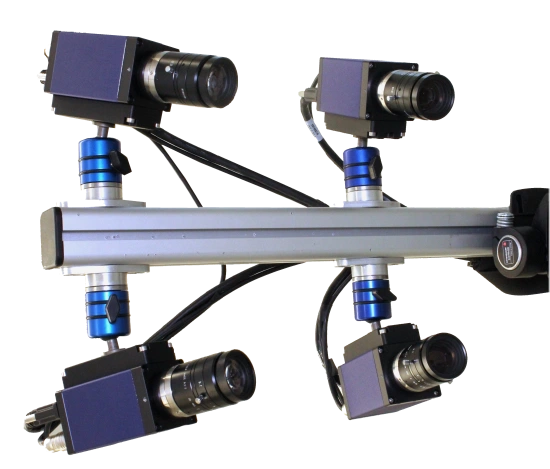

An outstanding feature of the AutoGrid® system is that it can be used with the same four-camera principle and identical evaluation methodology for both main applications of strain analysis: the determination of characteristic values in material testing laboratories and the analysis of formed parts. This means that the results of both measurement applications can be directly compared with each other with a high degree of reliability.

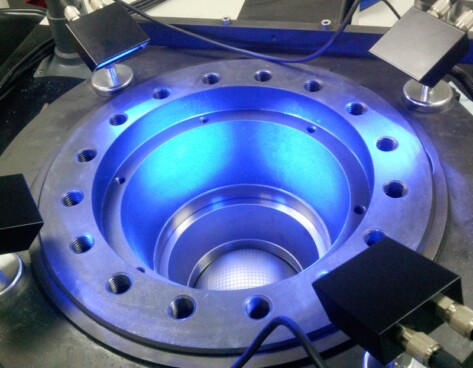

The AutoGrid® in-process system offers the ideal solution for integration into a sheet metal testing machine. Here, the evaluation of FLC tests represents a typical application. But this system solution has also proven itself in other applications, such as the determination of yield curves in bulge testing.

.

.

.

.

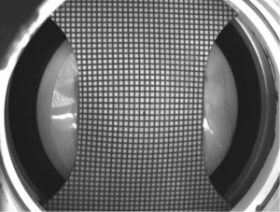

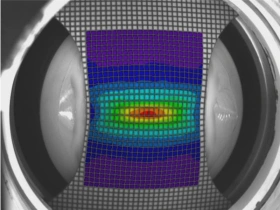

With the AutoGrid® in-process system, forming processes can be recorded and evaluated in motion if the area of interest is optically accessible to the cameras during the forming process. This enables time-dependent evaluation of material test trials, e.g. when determining forming limit curves (FLC). The image recording of all four cameras is precisely synchronized and takes place with an adjustable exposure time (e.g. 1/100 second) to enable evaluation during the movement of the measurement object.

.

.

.

.

Image recording rates of up to 20 image sets per second are possible. At the usual punch speed of 1-2 mm/s for the determination of FLCs, a temporal resolution of the punch displacement of at least 0.1 mm can be achieved. In many cases, lower image acquisition rates are already sufficient. In addition, it is possible to record analogue measuring values such as punch travel and punch force in parallel with image recording. These measured values can also be used to automatically start the image acquisition process when predefined values, such as punch stroke or punch force, are reached.

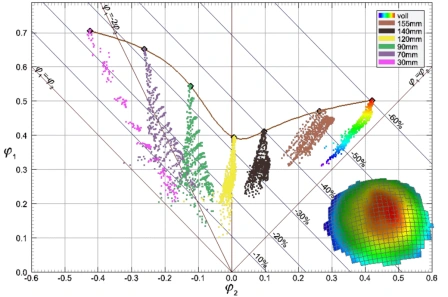

After the forming process, the entire image sequence is saved and available for further analysis. The step-by-step display of the sequence allows the user to select the point in time that is to serve as the basis for determining the FLC, e.g. the image before the start of the critical necking or before the crack. This eliminates the need for a quick stop of the testing machine or indirect conclusions from strain analyses after material failure. With the AutoGrid® system, the results are available approx. 5 minutes after the test trials. The results of the different FLC specimen shapes are automatically displayed in the forming limit diagram as FLC points. The FLCs can be displayed as a polygon line or with spline functions and exported as a data file.

The AutoGrid® in-process system is a tool for fast and objective evaluation of FLC tests, which can be used to determine the forming behaviour of sheet metal products, check incoming material and provide suitable material data for numerical simulation. The implemented evaluation methods comply with the specifications of ISO 12004. The flexible adaptable measuring head allows the use of the AutoGrid® in-process system also for other material tests, such as tensile test, bulge test or tube burst test.

.

.

Technical specification data:

.

.